Even though much has been written about the Worshipful Company of Turners since its award of a Royal Charter by King James I in 1604, much less is known about its earlier history as a Guild, and as the Old Turners’ Company – up to the end of the 16th Century.

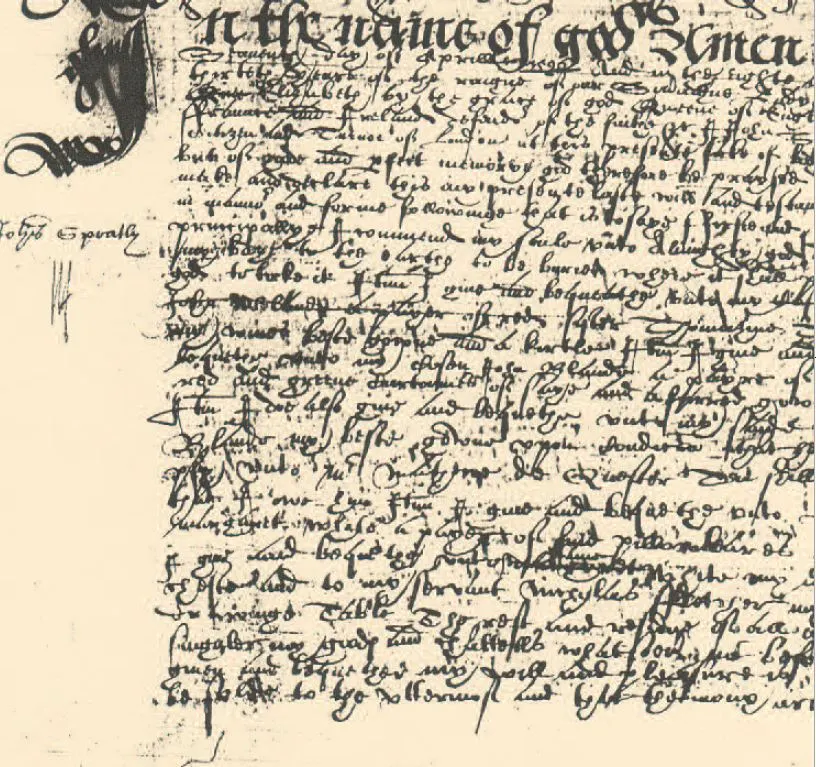

Ordinances of 1608

From the Ordinances of 1608 we know a great deal about the contemporary administration, bureaucracy and governance of the Worshipful Company and also of the importance of turner certified wooden measures of volume – and that shovels, scoops, washing bowls, chairs, wheels, pails, trays and truggers should be “workmanly wrought with good and sound stuff”.

However the complete and detailed 1608 Ordinances of the Company have been omitted from the two relatively modern editions of the Roland Champness History of the Turners’ Company.

The detail gives an additional insight into the pre-1604 Company; this can only be found in the 1925 first history of the Company written by Court Assistant A C Stanley-Stone – and created through the generous sponsorship of scholarly Past Master, Henry Llewelyn Howell. Here we read of another vital component of the Turners’ Craft. In Paragraph 39:

“Whereas for want of authority in the Master and Wardens to punish offenders many great abuses have been committed for making Blocks, Sheaves, Deadmens eyes, Ribs, Trundles for Barrel pumps, pumpboxes for ships, Rammers, Sponge heads, fire trunks & other necessaries to the great damage and hurt of His Majesty’s Navy, by reason of their being artificially made with very bad and insufficient stuff, to prevent which, it is ordered that no person shall make or turn such blocks, within the precincts, of any other wood than Ash, Elm, Beech or Hornbeam, & all sheaves to be made of Lignum Vitae, Elm, Beech, Maple or Hornbeam & all the pins that the sheaves run upon shall be made of Lignum Vitae, Brazil, Box, Holly, Hornbeam or Whitethorn, sound and workmanlike turned, all Deadmens eyes of Ash, Oak, Beech or Maple, & all Ribs and Trundles for the parrells (gear surrounding the mast), shall be made of Ash, Elm, Beech or Maple, & lastly all rammers, sponge heads, fire trunks & other provisions for the Gunner shall be made in workmanlike manner of such woods they are used to be made and if any person make such commodities of any other sort of wood or in any other manner he shall forfeit 10 shillings, & if the Master, Wardens & Assistants in any of their searches find any faulty commodities they may break & cut the same in pieces, & a penalty of 20 shillings shall be paid in case of resistance”

The Turners of London clearly had a significant role in the fitting-out of His Majesty’s ships in London, (the Navy of HM King James I of England and VI of Scotland) – working in, and with, London’s two great naval dockyards at Deptford and Woolwich.

Creation of the Royal Navy in 1660

The British Army was not created until the English Long Parliament created the New Model Army in 1645. The official history of the Royal Navy is said to have only began in 1660. Before then the English Navy had no defined moment of formation and tended to be an assortment of “King’s Ships” assembled when needed and then dispersed. But they were far from being ordinary ships.

The King’s Ships were permanently available to the Monarch and had to serve a number of purposes: Vehicles of Diplomacy and Symbols of Prestige as well as a means of Trade, Transportation and Warfare.

There were only a few King’s Ships – they couldn’t transport a whole army or win a war at sea – but in their day they were immensely powerful symbols in both a military and a political sense. These were the ships of His Majesty’s Navy referred to by the Turners’ Ordinances of 1608.

Discoveries through maritime archaeology

The use of turned components on ships at sea dates from long before the London Guild of Turners and back to the early days of turning and the very earliest days of sail. The exciting new field of maritime archaeology is constantly making fresh discoveries from ancient ships: turned pulley wheels have been found on Greek cargo vessels dating from around 300 BC.

Archimedes invented the compound pulley in about 250 BC and by about 100 AD Roman cargo ships were using halyard blocks (for raising the sails), turned dead-eyes for tensioning the main-stays and shrouds (supporting the mainmast) and pulleys on the running rigging (controlling the yards and the sails).

Role of the Crusades

Northern European shipping design was for 500 years dominated by Viking longships with their dependence on oarsmen and a single mainsail. The widespread use of pulley power with blocks and sheaves made by turners was essentially Mediterranean; but the Crusades, and to a lesser extent ocean trade, brought about a substantial transfer of shipbuilding techniques between the Mediterranean and the rest of Europe.

The Agincourt invasion fleet

Henry V needed Carpenters and Turners, with their Masters, as much for the maintenance of the hundreds of ships in his Agincourt invasion fleet as for his land army and their siege engines. By the 15th Century sailing vessels were festooned in standing and running rigging. The turners’ craft was much in demand by shipbuilders.

Christopher Columbus and the Santa Maria

When Christopher Columbus set sail westwards in 1492 in the Santa Maria, the state-of-the-art ocean going ship was three-masted and a hybrid of northern European concepts like square sails and stern, and a rudder and tiller, and the proven Mediterranean components of multi-decks, lateen sails and powerful rigging for sailing close to the wind. Sailing had now become totally dependent on reliable blocks, tackles and standing rigging.

Henry VIII and the Mary Rose

Henry VIII acceded to the throne of England in 1509, at the age of 17, and by the end of the year had commissioned two Great Ships, the Mary Rose and the Peter Pomegranate. Then in 1513 -1514 he built two substantial Royal Dockyards at Deptford and Woolwich on the Thames – to enable fitting out near the Royal Armouries in the Tower of London and with access to a pool of skilled London craftsmen.

It is from the Mary Rose, fitted out in London, and now in its magnificent new Museum at Portsmouth Historic Dockyard, that we know so much about turners’ workmanship in a Tudor warship.

Importance of the turners’ craft to the Mary Rose

On the Mary Rose we can see that the shrouds, 2 inch diameter ropes, were attached to the top of the mainmast and their lower ends fastened through deadeyes. Swifters were blocks and tackles which could be slacked when the yards (horizontal cross beams holding up the sails) were braced around when sailing to windward. Running rigging controlled the sails and yards through a further series of ropes, pulleys and blocks. Sheets, the ropes controlling the bottoms of the sails ran through more blocks – and parrells were used to raise and lower the yards. The Mary Rose literally used thousands of turned components.

Lignum vitae – the wood of choice

Henry VIII died in 1547 by which time he had built his navy up to 40 ships including five Great Ships. By some he has been called the father of the Navy. It was also during Henry VIII’s reign that lignum vitae, a dense tropical hardwood reputedly discovered by Christopher Columbus, was adopted by turners as a wood of choice for sheaves because of its remarkable durability and self-lubricating properties.

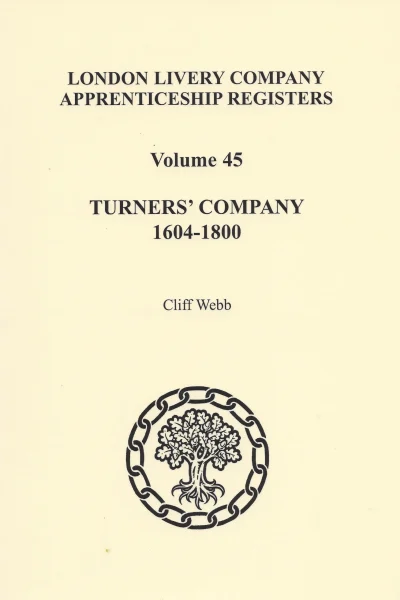

The Turners’ apprentices

Inevitably many turners’ apprenticeships became associated with London shipbuilding and fitting out. The Society of Genealogists in 2014 published a complete record of Turners’ Company apprenticeships from 1604 to 1800. Here one can see the many names of Anchorsmiths, Blockmakers, Boatbuilders, Caulkers, Mariners, Mastmakers, Pulleymakers, Pumpmakers, Riggers, Ropemakers, Sailmakers, Sailors, Ship’s Carpenters, Shipwrights and Staymakers who all apprenticed their sons to learn the turning craft.

Keeping the ‘Turners’ Mistery’

At one point the Turners’ Company became fearful that Pulleymakers and kindred trades might “learn the secrets of the Turners’ Mistery”. In 1607 a Search was made “within and without” the City of London of all the Pulleymakers “for bad made wares”; the searchers went to Deptford, Wapping, Fenchurch Street, London Wall, Bedlam, Blackfriars, Newington and Southwark inspecting wares and inquiring into the number and quality of the apprentices employed. Pulleymakers who could not clearly show that they had served proper turning apprenticeships were obliged to pay a considerable fine to be made free of the Turners’ Company.

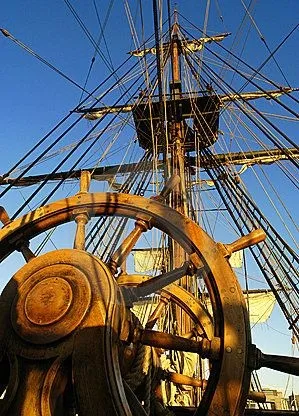

Invention of the ship’s wheel

One of the great marine inventions of the early 18th century was the ship’s wheel – first seen on an English warship of 1705. The wheel was connected to the tiller, and thus to the rudder, through a series or ropes and pulleys and raised up to the quarter deck giving the helmsman a clear view of the ship’s sails. As well as providing the functional pulley wheels of the steering mechanism turners provided the beautiful shaping of the wheel spokes and spoke handles.

A gradual weakening of the role of the Turners of London

Turners’ craft apprenticeships associated with constructing sailing ships in and around London seem to have peaked in the 18th Century.

However, as Britain’s Navy and Merchant Fleet became increasingly influential on the world’s oceans, shipbuilding expanded beyond London and the increasingly silt prone River Thames. Naval Shipyards were developed at Chatham, Sheerness, Portsmouth and Plymouth with overseas yards in Gibraltar, Halifax and Jamaica. Scores of civilian shipyards developed in Belfast and Bristol, Clydeside, Humberside, Merseyside, Teesside and Tyneside. In those distant parts there was little the Turners of London could do to oversee their craft.

HMS Victory – the turners’ greatest achievement

The greatest achievement of London turners has to have been the fitting out of the 3,500 ton displacement HMS Victory. This “first-rate” ship, carrying over 100 guns, was built in a new dock at Chatham and launched in 1765. Shipbuilding records show that some 6,000 trees were used in her construction of which 90% were oak and the remainder elm, pine and fir, together with “a quantity” of lignum vitae (for sheaves). Refitted in 1803 HMS Victory was Admiral Nelson’s flagship at the Battle of Trafalgar when on 21 October 1805 she was sailed brilliantly, and under difficult wind conditions, to help win for the Royal Navy a sea battle which set the scene for over a century of naval domination of the seas.

The start of mass production

By the end of the 18th Century, the time of the Napoleonic Wars, the Royal Navy was needing over 1,000 blocks of different sizes for a typical ship-of-the-line and had an annual requirement of over 100,000 blocks. They were all hand-made by local contractors but quality was not consistent, supply was problematic and the cost was high. In 1803 the Navy commissioned its own blockmaking machines in Portsmouth Dockyard, a mass production marvel of its day, and by 1808 was producing some 130,000 blocks per year. The days of hand turning were over although lignum vitae wood was always used for the sheaves.

Expressions from the ‘Age of Sail’

Blocks and tackles from this Age of Sail created two well-known expressions in the English language “chock full” and “chock a block” both meaning no room for any more, full right up, – when the two blocks of a tackle meet together preventing any more purchase being gained.

Lignum vitae – used in the first Nuclear submarine

Turned lignum vitae continues to enjoy a special place for ships at sea. Because of its exceptional strength and self-lubricating qualities, sheaves for blocks, belaying pins and dead-eyes were made of the wood up until the very recent introduction of specialised marine synthetic materials.

For the same reason it has been widely used in water lubricated shaft bearings for ships and, famously, the aft main shaft strut bearings for the USS Nautilus, the world’s first nuclear powered submarine, were made of lignum vitae.

The Llewelyn Howell Memorial Trophy

Henry Llewelyn Howell was Master of the Worshipful Companies of Turners of London in 1910. He was a distinguished barrister, eminent public servant, a skilled turner, musician, scholar and the Past Master Turner who laid the foundations of the Company’s history. He knew nothing about maritime archaeology or the recovery of the Mary Rose but it is most fitting that his Memorial Trophy, a beautiful Silver Porringer, should be awarded to the Royal Navy for distinguished craftsmanship.

Can any items of the turners’ craft have had greater influence on world events than the pulleys and blocks used at sea ?

Past Master John Bridgeman CBE TD DL